General Information

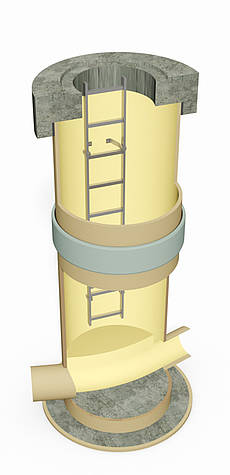

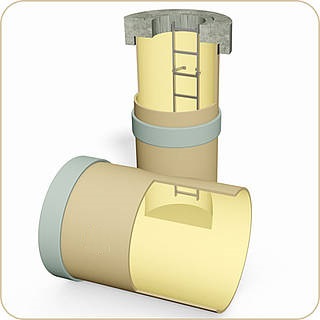

GRP manholes are made of RUSELBORU GRP pipes as integral part of pipe installations. Their design is based on RUSELBORU GRP pipes and GRP plates, joined together with the use of polyester - glass fibre laminates. The technology used in the production process of GRP manholes and chambers guarantees that they are completely sealed, fully corrosion proof, have excellent durability and can be safely serviced and maintained. Manholes and chambers are monolithic products with defined composition and properties.

Purpose

Manholes form a part of underground gravitational and pressure systems, allowing for the inspection and operation of pipelines and fittings, as well as for changing the flow conditions of a medium, within the range of their intended use. GRP manholes are primarily designed to be used for: inspection and maintenance of drains or sewers ventilation of drains or sewers flow conditions change of a medium (change of direction, change of pressure, change of water flow rate) cleaning and flushing of drains or sewers maintenance of water meters and fittings housing of pumping stations inlet drain pits

Quality Standards

All entities that manufacture manholes are certified according to ISO 9001 and other international and national production standards. During the production of the basic GRP elements, frequent checks are made on the flow of raw materials, machine speed and winder adjustments. Design and laminate specification of each manhole is permanently controlled to meet the requirements and standards of the customer’s specifications. The raw material components are periodically controlled with regard to quality, consistence and their physical/ chemical properties. The finished manholes and chambers meet the demands of prEN 15383 and the requirements on tightness according to EN 1610 after installation.

Features & Benefits

RUSELBORU GRP manholes consist of a composition of high tech materials and offer many features and benefits:

- Non-corrosive

- Durable Safe

- Maintenance-free

- Internal and external corrosion resistance

One-piece wall structure

- Restricts infiltration

- Avoids exfiltration

Lightweight

- Easy handling

- Unloading with light equipment

- No heavy equipment necessary for installation

Easy installation

- Savings in installation time

- Smaller excavation

- No heavy footings

- No waiting time for curing of the base plate before installation

- Easy fabrication: additional pipe entries can be cut with standard power tools

- No assembling on site

- Minor grouting necessary

- Easy inspection

Reliable product

- Dependable

- Dimensionally stable

- Uniform design