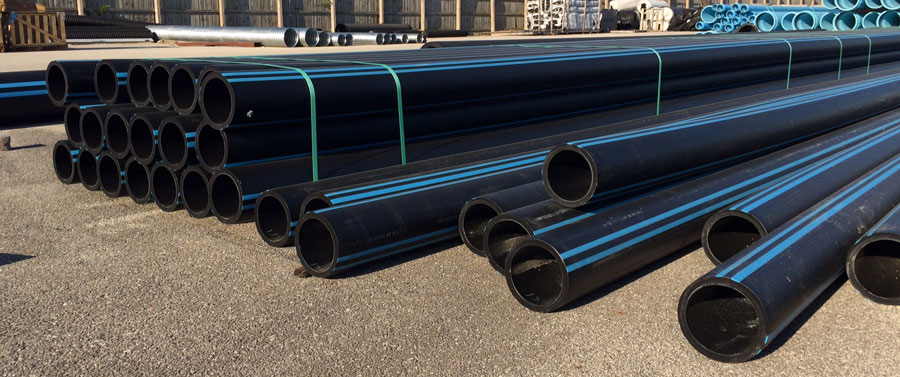

Over the years, PE100 materials have become recognised as the preferred choice to solve key industry challenges such as corrosion issues and high leakage rates - offering a new generation of leak proof, maintenance free and energy efficient pipeline systems.

RUSELBORU HDPE Pipe is designed and manufactured to meet the harsh climate related requirements in Africa, making them suitable for most applications. One of the most prominent features of HDPE pipe is the fact that a wide variety of jointing systems are available to suit the application and installation method, both new and existing. RUSELBORU also supplies a comprehensive range of fabricated HDPE fittings for pressure applications for a complete pipe solution.

Features & Benefits of HDPE Pipe

- High impact strength

- Damage Resistance

- Ease of Installation

- High Flow Capacity

- Long Life

- Trenchless Construction

- Good Chemical Resistance

- Flexibility

- Good Abrasion Resistance

- Good UV Resistance

- Cost-effective

HDPE pipes are mostly used in:

- Water supply lines

- Waste water lines

- Agricultural irrigation

- Drainage

- Transfer of chemical fluids

- Sleeve pipes for telecommunication and signalling cables

- Sleeve pipes for geothermal (thermally insulated) pipes

- Food and Beverage Industry

- Rainwater pipes and various other purposes

Advantages of PE pipes:

- Light and flexible

- Easy to assemble and join

- With a density of min 0,935 gr/cm³, it is approximately 8 times lighter than steel

- Not easily affected by underground movements due to its elastic structure

- Does not crystallize and continues to retain its elastic properties even when the temperature drops to -40°C

- Due to its flexible nature, pipes can turn 20 to 35 times the radius of the pipe diameter, whereby the use of elbows is diminished

- They are resistant to shocks and impacts; crack propagation resistance is high

- Long operational life. Given fluid temperature of 20°C within the pipe, a minimum of 100 years of operational life is expected. With non-thermal water sources of 7°C - 12°C, a minimum of 100 years of operational life is expected

- Resistant to chemicals and frost

- Low friction loss

- High resistance against sunlight

- Polyethylene is a thermoplastic product which can be recycled

- Does not release gas when on fire (an advantage over PVC pipes)

- Higher flaming temperature (an adventage over PVC pipes)

- No need for wide trenches while laying underground