By using the latest computer technology involved in GRP pipe manufacturing with RUSELBORU Centrifugal Casting, raw material distribution and raw material consumption are kept under control.

Theoretical and actual raw material consumption data are reported by the computer.

Following the entry of the class and diameter of the pipe to be manufactured into the computer, all manufacturing steps are controlled by the computer until the pipe comes out of the mold.

Manufacturing:

In RUSELBORU GRP pipes manufactured by the Centrifugal Casting method, glass fiber, polyester resin, and silica sand are used.

RUSELBORU GRP pipes, in this completely automatic and electronically controlled process, are manufactured by feeding the raw materials into the rotating mold, beginning from the outer surface of the pipe until reaching a predefined wall thickness. In this pre-programmed and continuously recurring process;

- Amount of raw material,

- Rotating speed of the mold,

- Pipe layers formed sheet by sheet

- And inner-cast temperature values are all measured.

A feeder leaves the amount of material, which is predefined in the system, within the mold. The resin that is formulated in a way that it is not polymerized during the whole process of loading, and the fibers that are cut with a length in compliance with the design are molded from the head at the end of the feeder.

Distribution and organization of the fibers within the layers are fabricated to counterbalance the resistance of the pipe in the designed circumferential and axial directions.

The mold, initially, is rotated relatively slowly. When the feeding of all the raw materials is completed, the cast rotation speed is increased in order to increase the compressive strength. By increasing the rotation speed of the mold, a full-compression and transition to a solid material (curing) are ensured.

By the reciprocating motion of the feeder within the mold, the wall thickness of the pipe is manufactured layer by layer. Glass fibers, which are reinforcing materials, are placed on both sides of the neutral axis on the pipe wall, and the gap remaining in between is filled by silica sand, resin, and glass fiber.

The mechanical properties of RUSELBORU GRP pipes are calibrated by changing the amounts, ratios, and direction of the material within the layers of the pipe.

Thus, the flexibility of the design of the pipes is enabled in a wide range of pressures, from non-pressure pipes to pressure pipes.

The type of resin used can be changed to meet the application requirement and ambient conditions.

Design of Wall Thickness:

As the system enables the even distribution of the glass fiber, identical wall characteristics within pipe layers are ensured regardless of the diameter, thus it is easy to determine the design and long-term properties of the pipe.

The layers of the pipes are polymerized in the form of “solid blocks”. Glass fiber distribution in the manufacturing process is kept completely under control, in line with the requirements of the circumferential and axial strength, by the use of varying cutters and mold speeds.

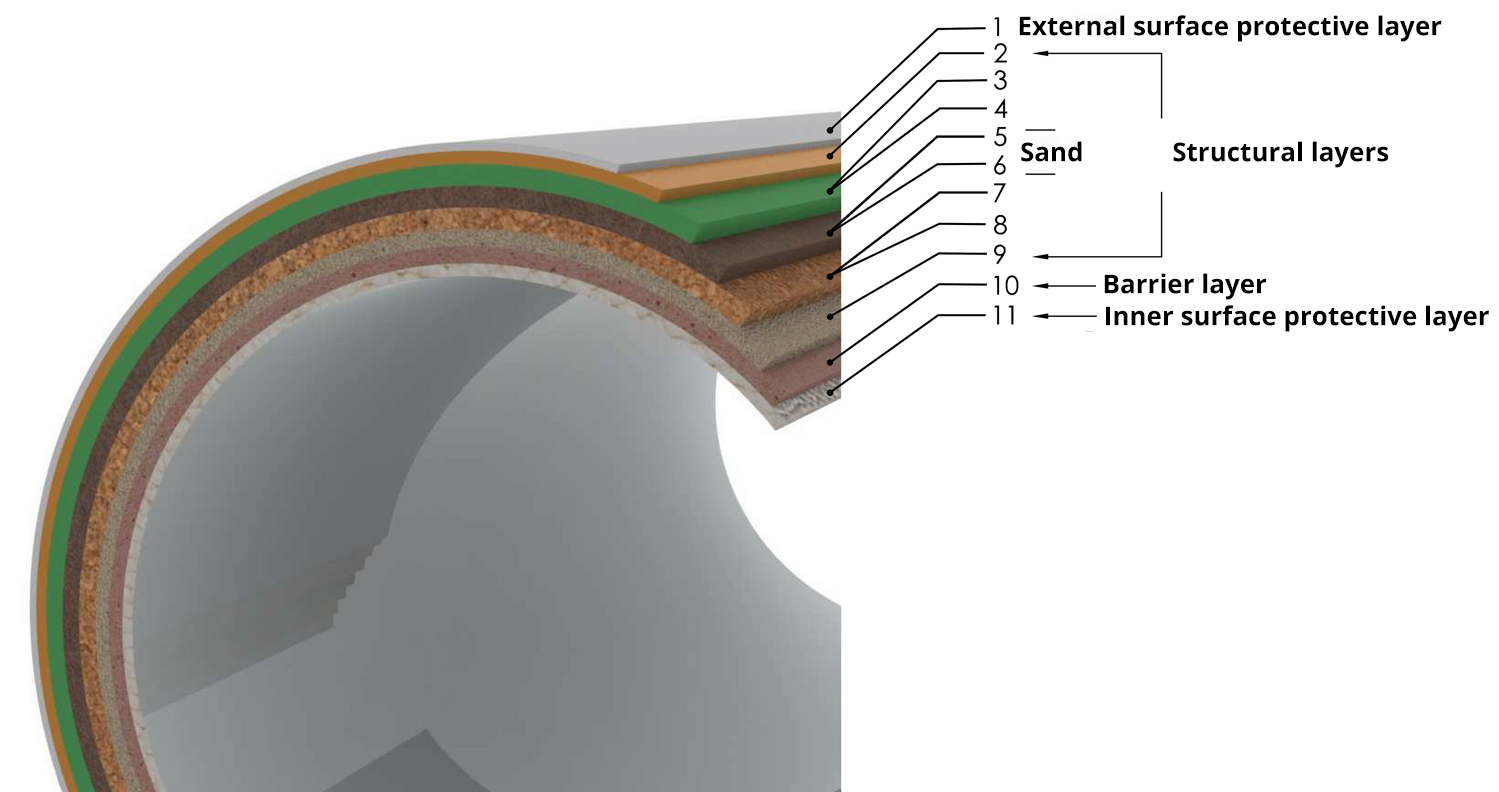

Each layer, forming the wall of the pipe, has a specific function. When the interior of the pipe is examined, a flexible resin layer, having no glass fiber on the inner surface, can be seen. The thickness of this layer, which is composed of a pure distinctive resin, is minimum 1 mm, and gives the pipe its hydraulic properties and a high abrasion resistance.

A barrier layer exists behind the liner layer. The liner and barrier layers, together, function to prevent the penetration of foreign substances into the structural layers of the pipe.

Behind the barrier layer is the structural layer, which differs in design according to the pressure and stiffness class of the pipe. On the external surface of the pipe there is the outer layer, which protects the pipe from impacts and scratches during the loading processes. This layer, additionally, protects the pipe against UV radiation penetration.